So You Want to Build an Autococker: The Ultimate Cocker Building Guide

Building an Autococker begins with a good guide. Learning what an Autococker is, usually starts like this …You’re on the field and you hear an intriguing sound. The shots — they sound — different. You’ve become mesmerized, maybe even hypnotized to the sound, a certain *clack-clack* and blur of a magical back block flying back and forth.

You may have even seen some of the elder statesmen running, and we use the term loosely, wild and shooting the glorious beast that is the Autococker.

Whatever your reason, you’re now determined you too must have one. But instead of buying one complete and set up, you want to build your own Autococker. A bold choice, my friend.

You may have even seen some of the elder statesmen running, and we use the term loosely, wild and shooting the glorious beast that is the Autococker.

Whatever your reason, you’re now determined you too must have one. But instead of buying one complete and set up, you want to build your own Autococker. A bold choice, my friend.

How the hell do you make your own Autococker?

What does what? What parts are the best? Is there really even a difference in buying an Autococker and building your own? I’ll be your Sherpa on this trip to paintball’s great mountaintop. Let’s start our build with the basics.

HMM - Sexy Body You Got There

Start off with what type of body you want, and can afford. This can vary wildly depending on your budget. Your high-end bodies can range into the thousands (not kidding), while your more budget-friendly can be under $100. There are a few things that actually matter here, and it’s not what it looks like. Contrary to what you have heard, size does matter.

What does what? What parts are the best? Is there really even a difference in buying an Autococker and building your own? I’ll be your Sherpa on this trip to paintball’s great mountaintop. Let’s start our build with the basics.

HMM - Sexy Body You Got There

Start off with what type of body you want, and can afford. This can vary wildly depending on your budget. Your high-end bodies can range into the thousands (not kidding), while your more budget-friendly can be under $100. There are a few things that actually matter here, and it’s not what it looks like. Contrary to what you have heard, size does matter.

Pre-2K bodies refer to bodies made prior to the year of our lord, 2000AD. These have smaller valve chambers upfront, and you can spot them by looking at the banjo bolt up front. This is the bolt that holds the front block on and is directly under the barrel. This is much smaller on a pre-2k body than one of a post-2k.

That is your dead-giveaway. Does it matter in a practical sense? Not a lot, unless you are building a mini cocker. Pre-2k bodies also can lack the tapping in the bottom tube for a screw-in Internal Velocity Governor or IVG. Instead, they use a cartridge-style velocity adjuster. These are sleeved tubes with a screw that moves in or out to adjust the tension on the hammer screw. Something to remember should you decide to build one.

The mini cocker just refers to where the front of the body starts. In a full-length Autococker, the body has space for a vertical ASA (where your regulator screws into) between your grip frame and your front block.

In a mini cocker, the body is chopped down or designed to be shorter, with the vertical ASA screwed directly into the front block or integrated with the front block itself. It’s called a mini because it’s shorter. Pretty straightforward. The guys who designed it were engineers, not wordsmiths.

This matters as pre-2k mini cockers are prone to trouble maintaining velocity shooting at high speeds if not run at high pressures. This is due to not having enough volume for air upfront without a volumizer or low-pressure chamber (LPC) upfront. A volumizer is a larger, extended bano bolt with an air chamber built-in. This can solve the problem, but also can make things pretty tight upfront when it comes time to mount your pneumatics and their friends, the hoses. If you’re going pre-2k and decide that a mini cocker is for you, it’s something to know.

Post-2k WGP bodies have a larger air chamber upfront, and therefore the larger banjo bolt. These are the most common floating around. Among these are the Prostocks, Super Stocks, mirror-milled slab bodies, and WGP smaller run bodies like Orracles and Karnivors. There are also a ton of private label milled bodies floating around available for builds with the same dimensions.

Most are compatible with your standard parts that you’ll see for sale, however, a few are a bit different. Here are the weirdos:

Merlins

These bodies use an 11/16ths valve and tend to have very simple milling styles. They also have wire detents with elongated detent covers. They were made at a time when valve chambers were not that large and went decidedly in the other direction. They have an enlarged valve chamber and specifically were made as part of a system for lower operational pressures.

Merlins

These bodies use an 11/16ths valve and tend to have very simple milling styles. They also have wire detents with elongated detent covers. They were made at a time when valve chambers were not that large and went decidedly in the other direction. They have an enlarged valve chamber and specifically were made as part of a system for lower operational pressures.

Meteors

These bodies have a few differences built into them. They are cut to 11/16ths valve size and have an insert in the lower tube in front of the valve that actually allows for the use of pre-2k front blocks with the larger valve style. They are factory cut with reverse p-blocks to shorten them as well. Their new bodies accept the empire style feed necks and Spyder style ball detents.

These bodies have a few differences built into them. They are cut to 11/16ths valve size and have an insert in the lower tube in front of the valve that actually allows for the use of pre-2k front blocks with the larger valve style. They are factory cut with reverse p-blocks to shorten them as well. Their new bodies accept the empire style feed necks and Spyder style ball detents.

Ressurections

These 11/16ths valves use their own version of a front block that only fits this style of body, and frames that will not fit the standard cocker. They are factory half-blocks as well. If you commit to this route, you’ll need to know that the body, front block, and frames will all need to be factory Resurrection or their style parts from Inception Designs. The detents are also spyder style, with rubber fingers reaching into the body and grabbing the ball.

These 11/16ths valves use their own version of a front block that only fits this style of body, and frames that will not fit the standard cocker. They are factory half-blocks as well. If you commit to this route, you’ll need to know that the body, front block, and frames will all need to be factory Resurrection or their style parts from Inception Designs. The detents are also spyder style, with rubber fingers reaching into the body and grabbing the ball.

SR Autocockers

These funky little Autocockers have 11/16ths bodies. They also have front blocks that have built-in electronics and pneumatics, as well as the hands-down goofiest frame in the Autococker world. And, just for fun, they also have boards with no aftermarket support and screens that die. They aren’t bad looking bodies, but the extra parts that come on one stock leave a LOT to be desired.

These funky little Autocockers have 11/16ths bodies. They also have front blocks that have built-in electronics and pneumatics, as well as the hands-down goofiest frame in the Autococker world. And, just for fun, they also have boards with no aftermarket support and screens that die. They aren’t bad looking bodies, but the extra parts that come on one stock leave a LOT to be desired.

05 Black Magics

These come half-blocked with flame-y milling on the back of the upper tube and trilogies are different in their lower tube. Instead of the 9/16ths valve, they take 11/16ths valves. They are also factory mid-blocked, meaning they don’t use a back block.

These come half-blocked with flame-y milling on the back of the upper tube and trilogies are different in their lower tube. Instead of the 9/16ths valve, they take 11/16ths valves. They are also factory mid-blocked, meaning they don’t use a back block.

Trilogies

These are 11/16ths valved and also integrate the three-way into the body, along with the Vertical ASA. WGP was trying to break into the entry-level market with these markers, and this was their attempt. They are perfectly acceptable entry-level bodies. That said, they are not looked at the same way as most other cockers because they lack a front block, and have integrated their 3 ways, integrated ram mount, and need a different style of LPR.

These are 11/16ths valved and also integrate the three-way into the body, along with the Vertical ASA. WGP was trying to break into the entry-level market with these markers, and this was their attempt. They are perfectly acceptable entry-level bodies. That said, they are not looked at the same way as most other cockers because they lack a front block, and have integrated their 3 ways, integrated ram mount, and need a different style of LPR.

Inception Designs

Inception Designs also makes bodies that have different dimensions, and it’s something to be aware of. There are two main two types of bodies that he currently produces, and there are notable differences here as well. Simon, the owner of Inception Designs and inventor of several things paintball, made bodies using 11/16th valves that are compatible with Resurrection parts and then those with WGP. The WGP-compatible bodies are his retro series.

Both take 11/16ths valves and there is a subtle but incredibly important difference in the upper tube. They have a larger diameter in the upper tube than a standard cocker body and need the same size o-rings on the bolt as your tank. They also should be harder o-rings that glide well. If you try to use a normal bolt without o-rings or one with standard cocker-sized o-rings, you’re going to have a bad time. This is your warning! It will lead to blowback, broken paint, and broken dreams.

Inception Designs also makes bodies that have different dimensions, and it’s something to be aware of. There are two main two types of bodies that he currently produces, and there are notable differences here as well. Simon, the owner of Inception Designs and inventor of several things paintball, made bodies using 11/16th valves that are compatible with Resurrection parts and then those with WGP. The WGP-compatible bodies are his retro series.

Both take 11/16ths valves and there is a subtle but incredibly important difference in the upper tube. They have a larger diameter in the upper tube than a standard cocker body and need the same size o-rings on the bolt as your tank. They also should be harder o-rings that glide well. If you try to use a normal bolt without o-rings or one with standard cocker-sized o-rings, you’re going to have a bad time. This is your warning! It will lead to blowback, broken paint, and broken dreams.

These bodies also use the Spyder style finger detents. They also can only use frames by Inception Designs without being milled, or Resurrection frames.

It is also important to note that Simon’s original run of Fighter, Kryptonite, Ripper, and FLE bodies was actually machined to WGP blanks and used stock WGP parts, including the standard 9/16ths valve. So if you are looking at going that route, make sure that your lower tube is the correct size. These also have normal-sized upper tubes as well, so most aftermarket bolt options will work just fine.

Kracken

Killshot Kustoms made some pretty custom bodies in a small run over the past couple of years. They have hooking rings across the back, and it ended up with a stunning look. These also take 11/16ths valves.

What's Your Flavor?

Other options for the body may sound a bit goofy. There are midget bodies, half-block, and midblock.

The midget bodies are cut so that the back of the body lines up with the end of the frame. I would recommend against this for a first build, as it’s one of the most difficult to set up properly and get to usable velocity without using an electronic valve. They’re incredibly small and light, but sometimes that’s not a great thing. It’s better to have something that works and is a little heavier than light and maxing out at 250 fps. It is possible to get to velocity with the right springing, but again, wouldn’t recommend for a first build.

It is also important to note that Simon’s original run of Fighter, Kryptonite, Ripper, and FLE bodies was actually machined to WGP blanks and used stock WGP parts, including the standard 9/16ths valve. So if you are looking at going that route, make sure that your lower tube is the correct size. These also have normal-sized upper tubes as well, so most aftermarket bolt options will work just fine.

Kracken

Killshot Kustoms made some pretty custom bodies in a small run over the past couple of years. They have hooking rings across the back, and it ended up with a stunning look. These also take 11/16ths valves.

What's Your Flavor?

Other options for the body may sound a bit goofy. There are midget bodies, half-block, and midblock.

The midget bodies are cut so that the back of the body lines up with the end of the frame. I would recommend against this for a first build, as it’s one of the most difficult to set up properly and get to usable velocity without using an electronic valve. They’re incredibly small and light, but sometimes that’s not a great thing. It’s better to have something that works and is a little heavier than light and maxing out at 250 fps. It is possible to get to velocity with the right springing, but again, wouldn’t recommend for a first build.

Half block and midblock bodies are cut down to eliminate the use of a back block. While they are the gingers of the Autococker world in that they have no soul, like redheads they are uncommon, and some people still desire them.

Halfblocked bodies have half the upper tube cut down and have replaced the back block with a sled that rides along the lower tube with the bolt and sled exposed. Likewise, midblocks ride on a sled (editor’s note: Wheeeeeeeeeeeeeeeeeeeeee!!!) but instead of cutting off the upper tube completely, it is milled through to allow the bolt to remain covered within the body. Both then use a vertical pin to connect it to the hammer that sits below. See the 05 Black Magic for a great representation of a mid-block, or this beautiful mid-block trilogy.

Halfblocked bodies have half the upper tube cut down and have replaced the back block with a sled that rides along the lower tube with the bolt and sled exposed. Likewise, midblocks ride on a sled (editor’s note: Wheeeeeeeeeeeeeeeeeeeeee!!!) but instead of cutting off the upper tube completely, it is milled through to allow the bolt to remain covered within the body. Both then use a vertical pin to connect it to the hammer that sits below. See the 05 Black Magic for a great representation of a mid-block, or this beautiful mid-block trilogy.

Ok, so already you’ve seen that in just the body, there are a lot of options. That’s okay! Pick the one you like and dive into it. Learn about it before you try and pick up the others, and you won’t get overwhelmed.

Gentlemen, Start Your Engines

Here, we’re talking about the lower tube of your marker. You thought I’d be talking about the pneumatics, didn’t you? Well, the lower tube is actually the engine of the marker, and should be extremely familiar to anyone who has ever shot a mechanical poppet valve marker. It’s a stack that goes in this order, from business end-to-beavertail. First, there is a valve spring, which presses a cup seal and stem closed on your valve.

Gentlemen, Start Your Engines

Here, we’re talking about the lower tube of your marker. You thought I’d be talking about the pneumatics, didn’t you? Well, the lower tube is actually the engine of the marker, and should be extremely familiar to anyone who has ever shot a mechanical poppet valve marker. It’s a stack that goes in this order, from business end-to-beavertail. First, there is a valve spring, which presses a cup seal and stem closed on your valve.

There are, as I briefly touched on shortly earlier, two sizes of valves. The 9/16ths is the standard size for most valve bodies, and what fits in most WGP-based marker. There is also the 11/16ths valve, which goes in the bodies that I listed above. If you have any questions on which you need, take apart your lower tube and look down it.

If you can’t see straight down the body, or notice threads in the middle of the body, you have a 9/16ths valve. If you can see a uniform ID the entire way down the body or lacks threading internally midway through the body, its 11/16ths. That valve is held in place by a nut or possibly two nuts, depending on your valve size or if your Autococker had been in a horrific bicycle accident when it was younger.

If you can’t see straight down the body, or notice threads in the middle of the body, you have a 9/16ths valve. If you can see a uniform ID the entire way down the body or lacks threading internally midway through the body, its 11/16ths. That valve is held in place by a nut or possibly two nuts, depending on your valve size or if your Autococker had been in a horrific bicycle accident when it was younger.

If you are using a 9/16ths valve, which is standard for many cockers, you will have a drilled-through jam nut in the lower tube that holds the valve in place, along with another nut coming in from below the valve and pressed into the valve body to hold it in place. If you are using an 11/16ths valve, the nut coming in from the bottom of the body is what holds it where it should be.

Then, you have a hammer and the mainspring. On any Autococker with a soul, the hammer is attached to a cocking rod as well, which passes through the IVG or velocity adjuster that sits in the back. If you have a mid- or half-block, you won’t need the cocking rod, as the hammer and bolt are connected through the bolt and sled via pull pin. That is the entirety of your lower tube.

Spring>Valve>Hammer>Spring>Velocity Adjuster. Seems simple, and really is in terms of parts, right? Well, sort of.

Those parts actually determine a lot on your marker, depending on how you want to set it up. If you want a softer, more smooth set up, you are probably going to want to get a heavy hammer with a light mainspring and a low-pressure valve, like an AKA Tornado, Inception’s valve, or Shocktech Rat valve. If you too are like Eleanor Roosevelt and like hot, balls-out speed, you may opt for heavier springs that allow you to run a higher pressure while being efficient. There are a million different ways to go, depending on preference and your balance of efficiency and feel.

You can also get the entire lower tube in sets, and just build them like that, either from companies’ sites or from eBay. They generally will all do the job, it’s just preference. I also want to note that WGP made very good lower tube components as well, so do not just feel the need to swap them out because they’re stock (unless you have the very old stock parts with a small lug, then definitely swap one out for a modern version—these are uncommon to find nowadays).

The Eclipse Supercharger, among several other valves, is a close copy with an E milled into it that you will never see and a built-in upcharge and very slightly milled larger intake and exhaust ports, and almost no performance differences. Again, the stock valves are really good.

I really can’t stress how much springing really matters enough. The weights of your springing will affect your efficiency and your trigger pull. How do you ask? Your hammer and sear are in contact, with the pressure of the mainspring pushing your hammer and lug against your sear and affecting how your trigger will act. A heavier mainspring pushes your hammer forward harder and can put more pressure on your hammer lug.

If it’s rounded off to allow for a smoother release, this can be a problem, as the mainspring can cause it to slip. You’ll also need a heavier sear spring to counteract the pressure. The heavier the mainspring, the heavier your sear spring may need to be. The springing is a balance between several parts that affect both your efficiency and trigger pull.

Thunderbolts and Lightning

There are only a few things that you really need to know about bolts. The first thing is the bolt length. There are really 4 lengths. The first is the half bock/midblock size. These go with any of the bodies lacking a back block.

The next size is the Evo-length or p-block length. These are for bodies in which the back block is cut into the body itself. The next size up is the 2k+ length, and it goes with those bodies. You can tell if you need one of these by looking at the back block. If it’s thin with the pull pinhole about ¼” from the body, this is what you want. If it’s closer to ½” from the body, you want a pre-2k length.

Spring>Valve>Hammer>Spring>Velocity Adjuster. Seems simple, and really is in terms of parts, right? Well, sort of.

Those parts actually determine a lot on your marker, depending on how you want to set it up. If you want a softer, more smooth set up, you are probably going to want to get a heavy hammer with a light mainspring and a low-pressure valve, like an AKA Tornado, Inception’s valve, or Shocktech Rat valve. If you too are like Eleanor Roosevelt and like hot, balls-out speed, you may opt for heavier springs that allow you to run a higher pressure while being efficient. There are a million different ways to go, depending on preference and your balance of efficiency and feel.

You can also get the entire lower tube in sets, and just build them like that, either from companies’ sites or from eBay. They generally will all do the job, it’s just preference. I also want to note that WGP made very good lower tube components as well, so do not just feel the need to swap them out because they’re stock (unless you have the very old stock parts with a small lug, then definitely swap one out for a modern version—these are uncommon to find nowadays).

The Eclipse Supercharger, among several other valves, is a close copy with an E milled into it that you will never see and a built-in upcharge and very slightly milled larger intake and exhaust ports, and almost no performance differences. Again, the stock valves are really good.

I really can’t stress how much springing really matters enough. The weights of your springing will affect your efficiency and your trigger pull. How do you ask? Your hammer and sear are in contact, with the pressure of the mainspring pushing your hammer and lug against your sear and affecting how your trigger will act. A heavier mainspring pushes your hammer forward harder and can put more pressure on your hammer lug.

If it’s rounded off to allow for a smoother release, this can be a problem, as the mainspring can cause it to slip. You’ll also need a heavier sear spring to counteract the pressure. The heavier the mainspring, the heavier your sear spring may need to be. The springing is a balance between several parts that affect both your efficiency and trigger pull.

Thunderbolts and Lightning

There are only a few things that you really need to know about bolts. The first thing is the bolt length. There are really 4 lengths. The first is the half bock/midblock size. These go with any of the bodies lacking a back block.

The next size is the Evo-length or p-block length. These are for bodies in which the back block is cut into the body itself. The next size up is the 2k+ length, and it goes with those bodies. You can tell if you need one of these by looking at the back block. If it’s thin with the pull pinhole about ¼” from the body, this is what you want. If it’s closer to ½” from the body, you want a pre-2k length.

The most efficient bolts will have three o-rings, one on the tip, and one on both sides of the air inlet. These do a couple of things. The one on the tip prevents blowback and forces all of the air coming out of you bolt forward. Where else might it go without one?

Backward. The air will flow backwards towards your ball and feedneck. If you don’t have this seal, while most of the air pressure hitting the ball moves it forward, so pressure deflects back. This can blow up your feed neck and cause chops, and it’s less efficient. While it may not cause problems all the time, especially if you have your marker timed conservatively, it can be an issue for more aggressively timed markers or if your bolt isn’t really closely sized to your body. Just something to remember

Backward. The air will flow backwards towards your ball and feedneck. If you don’t have this seal, while most of the air pressure hitting the ball moves it forward, so pressure deflects back. This can blow up your feed neck and cause chops, and it’s less efficient. While it may not cause problems all the time, especially if you have your marker timed conservatively, it can be an issue for more aggressively timed markers or if your bolt isn’t really closely sized to your body. Just something to remember

And what about being less efficient? How much less, you ask? Well, the front o-ring alone can be worth 30-35 fps or so. The other two o-rings around your inlet also stop air from escaping from around the hole and can be worth about 10-15fps. Add that up and you could be looking at a 50fps increase in going from an o-ring-less to triple o-ringed bolt with zero other changes.

What Are the Differences Between Bolts?

Truthfully, not a whole heck of a lot. You want the airflow to be as unrestricted as possible to stay efficient, and again, three o-rings. You will want to likely avoid some bolts, as some venturi bolts have extremely restrictive designs (ie Evolution bolts), inserts (Bob Long Cyclones), or moving parts that make them a nightmare to time (Slingshot bolt — kill it with fire).

The Delrin bodies slide well and don’t need any oil. Aluminum will need oil. And Inception Bodies will require the larger, hard o-rings. Outside of that, odds are good that you won’t notice a difference between them practically. Pick one you like, slap it in there, and move on.

I Got This

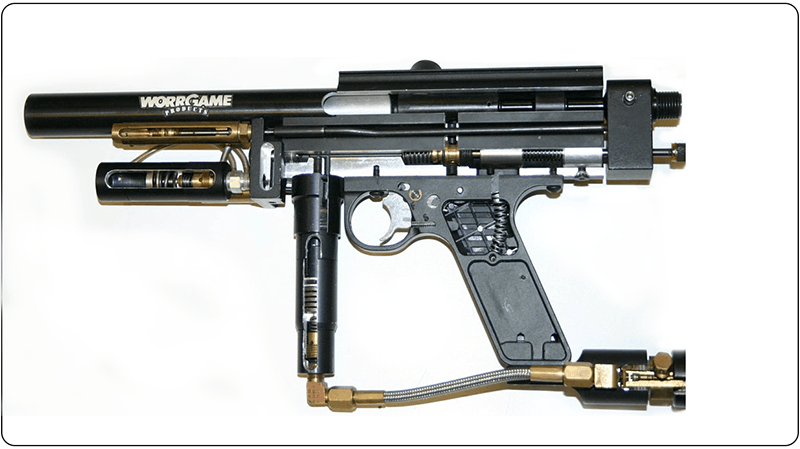

Autocockers are called Autococker for a reason. They are essentially pump guns that cut out the middleman and just do it their goddamn selves. They do this using their pneumatics upfront, also called “What are those?” by new players. The way they work isn’t too complicated once you get passed the way they look and just concentrate on what they are doing.

What Are the Differences Between Bolts?

Truthfully, not a whole heck of a lot. You want the airflow to be as unrestricted as possible to stay efficient, and again, three o-rings. You will want to likely avoid some bolts, as some venturi bolts have extremely restrictive designs (ie Evolution bolts), inserts (Bob Long Cyclones), or moving parts that make them a nightmare to time (Slingshot bolt — kill it with fire).

The Delrin bodies slide well and don’t need any oil. Aluminum will need oil. And Inception Bodies will require the larger, hard o-rings. Outside of that, odds are good that you won’t notice a difference between them practically. Pick one you like, slap it in there, and move on.

I Got This

Autocockers are called Autococker for a reason. They are essentially pump guns that cut out the middleman and just do it their goddamn selves. They do this using their pneumatics upfront, also called “What are those?” by new players. The way they work isn’t too complicated once you get passed the way they look and just concentrate on what they are doing.

Breaking it down, how an Autococker works, is to split it into two functions: making it go boom and resetting it. The making it go boom part is pretty simple. A shooter pulls the trigger, causing a sear to drop. That sends the hammer, which was being held in place by the said sear, rushing forward and hitting the valve stem. That releases air pressure through the valve, up through the body, and into the bolt. That pressure then sends a ball hurtling down your barrel and towards some poor, unfortunate soul downfield. That’s what happens in the initial part of your trigger pull.

As your finger keeps pulling back, it resets the marker. How does it do so? Your trigger has a bent rod connected to it, commonly referred to as a timing rod or actuator rod. This attaches to your three-way. Your three-way is attached to its partners in crime, the Low-Pressure Regulator (LPR) and ram. The LPR is sending the three-way a constant stream of air pressure to the three-way, and the three-way is acting as an air traffic controller. It sends air to one end of the ram or the other. The default setting to your trigger is pushing air to the base of your ram, holding your back block in the forward position.

When you pulled that trigger, you also moved the rod in the three-way. It shifted the pressure coming into it via the LPR from one side of the ram to the other. By doing this, the pressure has caused the back block to fly open, pushing the back block clear, and allowing a ball to load. By releasing the trigger, a spring in the frame resets your trigger plate to its starting position and the 3-way redirects that air back towards the base of the ram.

In addition to being important for obvious reasons, these are also the most replaced and more varied parts of an Autococker. There are literally hundreds of different part combinations that you can use here, and almost none of them will actually make a major performance difference on most mechanical autocockers. Here are the basics, along with the most common styles available.

Push it, Push it Real Good

In addition to being important for obvious reasons, these are also the most replaced and more varied parts of an Autococker. There are literally hundreds of different part combinations that you can use here, and almost none of them will actually make a major performance difference on most mechanical autocockers. Here are the basics, along with the most common styles available.

Push it, Push it Real Good

The ram is what actually pumps your marker. There are a few different styles. The first I’ll go over is the Clippard or Bimba style rams. Two examples of these are the free flow ram and the ANS miniram. They both have stainless steel bodies and aluminum ends, are smooth, reliable, and fast. The ANS miniram might be the fastest ram ever made for a cocker. Those are the positives.

Their downsides are that they go bad, you can’t fix them, they need a higher pressure due to the smaller diameter to run and means more pressure in your three-way which can cause binding and/or need stiffer springing. They are press-fit together, and you have no access to any of their parts or seals. They also cannot be anodized to match the rest of your marker. They’re the Humpty Dumpty of rams if Humpty spent his life kicking ass until he fell off that wall.

Their downsides are that they go bad, you can’t fix them, they need a higher pressure due to the smaller diameter to run and means more pressure in your three-way which can cause binding and/or need stiffer springing. They are press-fit together, and you have no access to any of their parts or seals. They also cannot be anodized to match the rest of your marker. They’re the Humpty Dumpty of rams if Humpty spent his life kicking ass until he fell off that wall.

The next common type of ram is the STO style ram. They come with aluminum bodies, plated or steel base, and barbs sticking out of the base and end of the aluminum tube. Examples of this are the WGP STO, Shocktech, and KAPP rams. These work well, can be anodized, are able to be taken apart for maintenance and fixing and are generally the cheapest style. If there is a downside, it’s just in the looks department, as it’s just a colored tube with no fancy-pants milling. But they work great and can be made to match your marker.

The last style would be the English model. These are the Belsales ram and its derivatives. These would include the Evo rams, Planet Eclipse, Empire Resurrection, and Inception Gentle Touch rams. They’re all-aluminum construction allowing the entire ram to be anodized, have sleek rounded ends, are generally very smooth, and are also extremely fast. I have heard of quality control issues for Empires rams, so you may want to avoid them. They tend to be more expensive but work extremely well.

The Inception rams are of this style and have a larger diameter, a thicker shaft, and cuts in the shaft that allows for tools to grip them easier. The added girth allows for lower pressure so that your balls get pinched instead of chopped in the event of a bad feed. The downside of this is that you need to be very careful when timing your marker.

Here’s why. Here’s a hint. It’s user error.

The larger diameter means lower pressure to deliver the same force, but the force on the paintball is the same either way. The larger shaft of the Inception ram means you have less surface area for the pressure to work on for the forward stroke specifically, so you have a fast back-cocking, but a softer return which presumably means less of a chance for a chop. This also means the block isn’t held forward as strongly. Sometimes this can lead to user error. When the pressure set too low, this can lead to back-block jump on the fire resulting in blow-back. This won’t be seen dry-firing but will show up when the paint is in the barrel and is thus often missed when ‘guns are timed dry. If you’re running into this problem, simply adjust the HPR up and you should be good to go. Just something to know if you go this route, as they are very good rams.

Ménage à Trois

Three Ways really fall into one of two categories, with those being two or three o-ring shafted three ways. The outside of the bodies of the three ways will all look relatively similar. You have your three barbs sticking straight up, coming out of an aluminum or brass body. The internals are what matter here.

The Inception rams are of this style and have a larger diameter, a thicker shaft, and cuts in the shaft that allows for tools to grip them easier. The added girth allows for lower pressure so that your balls get pinched instead of chopped in the event of a bad feed. The downside of this is that you need to be very careful when timing your marker.

Here’s why. Here’s a hint. It’s user error.

The larger diameter means lower pressure to deliver the same force, but the force on the paintball is the same either way. The larger shaft of the Inception ram means you have less surface area for the pressure to work on for the forward stroke specifically, so you have a fast back-cocking, but a softer return which presumably means less of a chance for a chop. This also means the block isn’t held forward as strongly. Sometimes this can lead to user error. When the pressure set too low, this can lead to back-block jump on the fire resulting in blow-back. This won’t be seen dry-firing but will show up when the paint is in the barrel and is thus often missed when ‘guns are timed dry. If you’re running into this problem, simply adjust the HPR up and you should be good to go. Just something to know if you go this route, as they are very good rams.

Ménage à Trois

Three Ways really fall into one of two categories, with those being two or three o-ring shafted three ways. The outside of the bodies of the three ways will all look relatively similar. You have your three barbs sticking straight up, coming out of an aluminum or brass body. The internals are what matter here.

Generally, the fastest three ways are those with three o-ringed shafts. These all stem from the Shocktech Bomb and include the Empire three-way and Inceptions v1 and v2 three ways. They shift air solely based on their middle o-ring traveling over the central air inlet (where the LPR feeds air into) and redirecting it. They also use smaller o-rings than the 2 o-ringed three ways, with the Inception v2 taking it to an extreme level, using by far the smallest o-rings and inlet ports in the game. This allows for an extremely short trigger pull, leading to really high bps for a mechanical marker.

The other option is the two three-way o-rings. It was what cockers started with and is literally every other three-way on the market. A modern example of one of these would be a Freeflow bullet. They work by the pressure in the middle being a constant, with air being redirected based on where the outer o-rings reside. These are slower in three ways, but very reliable and easy to time. They use slightly thicker o-rings as well. You can literally just look at them from the front and see if they are in the correct spot by pulling the trigger.

The other option is the two three-way o-rings. It was what cockers started with and is literally every other three-way on the market. A modern example of one of these would be a Freeflow bullet. They work by the pressure in the middle being a constant, with air being redirected based on where the outer o-rings reside. These are slower in three ways, but very reliable and easy to time. They use slightly thicker o-rings as well. You can literally just look at them from the front and see if they are in the correct spot by pulling the trigger.

There are two exceptions to the rule here. The Orracle and Palmer’s three ways are both very fast two o-rings three ways. They may look the same on the outside and the shafts look similar, but they both use internals that allows for much shorter switching. If you are looking for a faster three-way with a two o-ring design, these are the way to go.

What you’re looking for when trying to figure out faster or slower with the three ways are primarily two things. How big are the barb’s inlet holes, and how big are the o-rings on the three-way shaft? The smaller the inlets and o-rings, the faster it can flip as a general rule.

Regulators, Mount Up

The last little buddy you’ll be thinking of grabbing is your Low-Pressure Regulator (LPR). There are several types currently in production and worth using, as well as countless older ones that you can pick up used. I will caution you on Evil, Dye, Extreme Rage, and Smart Parts LPRs. They’re collectively about as trustworthy as a fart after Taco Bell.

What you’re looking for when trying to figure out faster or slower with the three ways are primarily two things. How big are the barb’s inlet holes, and how big are the o-rings on the three-way shaft? The smaller the inlets and o-rings, the faster it can flip as a general rule.

Regulators, Mount Up

The last little buddy you’ll be thinking of grabbing is your Low-Pressure Regulator (LPR). There are several types currently in production and worth using, as well as countless older ones that you can pick up used. I will caution you on Evil, Dye, Extreme Rage, and Smart Parts LPRs. They’re collectively about as trustworthy as a fart after Taco Bell.

The other type that you’ll likely want to avoid is the two oldest styles of WGP LPR’s, the Sledgehammers. The more common style here is the big, black or chrome bodies with smooth end caps. While you can definitely adjust them, you need to take the end cap off in order to do so. This can be a major pain. They are also very bulky and aren’t very user-friendly.

The other ones that you want to avoid are the older, slimmer brass LPRs. As one friend put it, they were red-hot garbage. These two WGP LPRs really aren’t what any real builder would want, and just are best avoided.

The other ones that you want to avoid are the older, slimmer brass LPRs. As one friend put it, they were red-hot garbage. These two WGP LPRs really aren’t what any real builder would want, and just are best avoided.

Palmers makes great LPRs that are fast, easily adjustable, and rebuildable. I have had to rebuild them more than any other LPR, but they consistently perform well after said rebuilds. The externally adjustable WGP LPRs are extremely good performers with generally simple looks and are some of the smallest and lightest LPRs available. The Inception and AKA LPRs are strong performers, rebuildable, and very consistent as well. Shocktech also makes a good LPR with a simple Schrader valve and comes with a stock knob. The Schrader valve allows it to be serviced as cheaply and easily as replacing a bike-tire valve. Choosing from this group really comes down to personal preference, as all will be strong performers.

Planet Eclipse and Belsales also made LPRs that go for hefty sums. While these LPRs can perform very well, there are a couple of red flags with them. They cannot be zeroed out, meaning you cannot turn them off. This can be a problem when troubleshooting. Also, they have seals that wear out and are not supported by either company or that can be easily gotten. They are nice parts but know that before you pay the premium price that they sell for on the used market.

Triggered?!?

One major decision that you will need to make is what kind of trigger frame you want on this majestic beast. There are two main categories that you’ll have to pick from, each with a couple of oddball options.

The classic Autococker frame is the slider. These triggers are pulled straight back and do exactly what they sound like to shoot and do their jobs in resetting the cycle. They slide. That’s it.

Triggered?!?

One major decision that you will need to make is what kind of trigger frame you want on this majestic beast. There are two main categories that you’ll have to pick from, each with a couple of oddball options.

The classic Autococker frame is the slider. These triggers are pulled straight back and do exactly what they sound like to shoot and do their jobs in resetting the cycle. They slide. That’s it.

It’s simple but extremely satisfying. Now, there are several variants in this group. The three current categories would be the standard 45 slider frame, the Shocktech Gunfighter frame, and Inception Designs sliders.

The regular 45 frame is a long-held standard, with the trigger plate riding between the top of the body and ledge under the trigger finger, pulled straight back against a spring. When you pull the trigger, it does a couple of things. It pulls your timing rod back and activates your three-way, and it moves a lever called the sear, which holds the hammer in your lower tube back. Your normal options here are the Benchmark, P&P, Dye, or Quickfire frames, with plenty of similar ones also on the market.

The sear rides with its nose on the trigger plate and its back end held up with a spring. When the trigger is pulled back, the front end of the trigger plate is pushed vertically, and the back end drops down, like a seesaw with a fat kid in the back. That sends your hammer forward and makes the gun go from party to business. The springs then push your trigger plate and sear back into their original places. The springing and lug depth controls if you have a long, smooth pull or a harder, snapper pull in conjunction with your three-way.

The Inception frames are also 45 frames and sliders but accomplish the same thing differently. Almost no parts are going to be interchangeable with a standard 45 frame. They run with wide internal channels and have wide plates and sears that won’t fit in most other frames. They also operate in a different way.

The sear rides with its nose on the trigger plate and its back end held up with a spring. When the trigger is pulled back, the front end of the trigger plate is pushed vertically, and the back end drops down, like a seesaw with a fat kid in the back. That sends your hammer forward and makes the gun go from party to business. The springs then push your trigger plate and sear back into their original places. The springing and lug depth controls if you have a long, smooth pull or a harder, snapper pull in conjunction with your three-way.

The Inception frames are also 45 frames and sliders but accomplish the same thing differently. Almost no parts are going to be interchangeable with a standard 45 frame. They run with wide internal channels and have wide plates and sears that won’t fit in most other frames. They also operate in a different way.

Instead of the trigger plate riding on your frame, it rides on two set screws. They have two styles of trigger plates with different angles on them to control if you want a shorter, more abrupt trigger, or a more classic, longer pull, as well as multiple springing options. The trigger geometry of the newer style makes it extremely hard to short stroke but can lead to a very different trigger pull.

The newest versions of the frames also have trigger stops in place to keep you from having over-travel. If you are thinking of heading this route, you may want to borrow one for a game or two and see which style you like more. A small change in the shape of a trigger plate can lead to entirely different feels for a gun.

The newest versions of the frames also have trigger stops in place to keep you from having over-travel. If you are thinking of heading this route, you may want to borrow one for a game or two and see which style you like more. A small change in the shape of a trigger plate can lead to entirely different feels for a gun.

Then you have the weirdos of the group (don’t take that as an insult, my own frame is a weirdo). We’ll start with Shocktech’s Gunfighter. It is also a slider using a trigger plate attached to a few levers, using a spring to connect them to the sear. The levers allow for an extremely short trigger pull by doing a lot of the work for you.

It does require a heavy spring to do this, which leads to what seems like a heavier trigger pull. In testing, it’s actually a similar weight to most sliders but feels the same with the weight of a sear on it as without. A normal slider feels different with weight bearing down on it. It also is best used with a three o-ringed three-way, Palmer’s Quickswitch, or Orracle three-way. These frames can shoot extremely quickly.

It does require a heavy spring to do this, which leads to what seems like a heavier trigger pull. In testing, it’s actually a similar weight to most sliders but feels the same with the weight of a sear on it as without. A normal slider feels different with weight bearing down on it. It also is best used with a three o-ringed three-way, Palmer’s Quickswitch, or Orracle three-way. These frames can shoot extremely quickly.

Another recent innovation to come to cockers are the Air-Through Frames. There are two different frames on the market, using a similar concept with regulators mounted in or on the frame. They then send air up to the area that the VASA would normally go by routing the air pressure through the frame, eliminating the need for an external HPR and macroline or stainless steel braid. While the concepts are the same, they go about it in slightly different ways.

The LNT frame has an Empire Axe on/off mounted at the bottom to regulator the air pressure for the marker. While these are a proven platform, they are an absolute pain to take apart if you want to do so for things like anodizing or servicing. It requires special tooling, and you are very unlikely to own it unless you also happen to own a paintball shop. As for the frame itself, I hadn’t used one, so I asked someone who had used one in-depth about their thoughts on it. He told me a few things. The trigger plate is aluminum, not very robust, and is off-center in the frame trigger. The pull feels a bit gritty and it takes some work to get a decent trigger pull. It also does not use standard sears, so you have to use their sear. The frame is a bit squared off as well, meaning not incredibly comfortable, and it uses the foregrip as a hollow expansion chamber.

The second option is the Nummech frame. It packs a custom on/off, custom regulator inside the frame, a regulator blow-off inside of the frame, and a gauge port to test the reg. The frame seals up against the top of the body, which means that you cannot use narrow bodies at the base. This hasn’t been a major issue for most bodies, but it did come up on a CCM S6 with removable vert ASA.

It uses standard sears and plates and has a very ‘finished’ feel. It compares well to the Inception 45 frame with the hump on the back and is very comfortable in the hand. The foregrip on this frame is just that, a foregrip, and is just there to make your hand happy and balance the marker. Nummech created several foregrip options, including a 2/3/4 knuckle, carbon fiber, angled, extended, and one modeled after the black magic regulator. Those are your two options for the air-through frames.

The LNT frame has an Empire Axe on/off mounted at the bottom to regulator the air pressure for the marker. While these are a proven platform, they are an absolute pain to take apart if you want to do so for things like anodizing or servicing. It requires special tooling, and you are very unlikely to own it unless you also happen to own a paintball shop. As for the frame itself, I hadn’t used one, so I asked someone who had used one in-depth about their thoughts on it. He told me a few things. The trigger plate is aluminum, not very robust, and is off-center in the frame trigger. The pull feels a bit gritty and it takes some work to get a decent trigger pull. It also does not use standard sears, so you have to use their sear. The frame is a bit squared off as well, meaning not incredibly comfortable, and it uses the foregrip as a hollow expansion chamber.

The second option is the Nummech frame. It packs a custom on/off, custom regulator inside the frame, a regulator blow-off inside of the frame, and a gauge port to test the reg. The frame seals up against the top of the body, which means that you cannot use narrow bodies at the base. This hasn’t been a major issue for most bodies, but it did come up on a CCM S6 with removable vert ASA.

It uses standard sears and plates and has a very ‘finished’ feel. It compares well to the Inception 45 frame with the hump on the back and is very comfortable in the hand. The foregrip on this frame is just that, a foregrip, and is just there to make your hand happy and balance the marker. Nummech created several foregrip options, including a 2/3/4 knuckle, carbon fiber, angled, extended, and one modeled after the black magic regulator. Those are your two options for the air-through frames.

The last ones weirdos that I’ll go into here are the slider frames with Reactive Triggers (R/T). I’m very biased towards these, as these are what I shoot extensively. There are two types of these frames, the BPS Reflex Kits and the updated version, the Annihilation Kits. Both use different front blocks up front with extra pneumatics and modified 45 slider frames with a ram behind the trigger plates. The extra parts up front are a second three-way with a slotted rod attached, a slide check on/off, and a splitter off the LPRs hose. There is also a tang that hangs from the pump rod into that slotted rod, longer bolt, drilled pump rods, and longer cocking rods.

The basic operation of these frames beyond normal Autococker changes things dramatically. When the trigger is pulled, the marker fires as it would normally. However, when the pump rod slides back, the tang on the pump slides back in the slotted rod and pushes it back to flip the extra three-way upfront. This sends pressure from the LPR through the three-way, on/off, and to the ram behind the trigger plate. When it does that, the ram fires off and pushes the trigger back to reset it extremely fast. The result is a mechanically selectable marker between R/T and semi that can fire as a practical full auto and rate of fire that you can lock in place with timing.

The longer bolt and cocking rod is actually there to slow down the system to allow it to be usable. When timed correctly you can set your trigger finger in place and allow the trigger to mechanically bounce and shoot very, very quickly, easily hitting 12+ bps on a mechanical frame. The downside of these frames is they are not cheap and very rare.

The longer bolt and cocking rod is actually there to slow down the system to allow it to be usable. When timed correctly you can set your trigger finger in place and allow the trigger to mechanically bounce and shoot very, very quickly, easily hitting 12+ bps on a mechanical frame. The downside of these frames is they are not cheap and very rare.

Swingers Club

The other option that you have is the swing or hinge frames. They all use a trigger that acts as a lever to move your three-way and drop the sear at once. Most are double triggers, although there are two companies that make or have made a single trigger. They are generally easier to shoot quickly than a slider frame. Some, including the WGP, Powerlyte, ANS, and Planet Eclipse are more adjustable than others.

When you pull a swing trigger, it’s more like pulling a traditional trigger for most paintballers. Instead of traveling straight back, it swings back and up, hence the name. Pulling the trigger drops your sear while also pushing your timing rod forward. These triggers are generally sprung pretty lightly and can shoot really quickly when set up correctly.

The other option that you have is the swing or hinge frames. They all use a trigger that acts as a lever to move your three-way and drop the sear at once. Most are double triggers, although there are two companies that make or have made a single trigger. They are generally easier to shoot quickly than a slider frame. Some, including the WGP, Powerlyte, ANS, and Planet Eclipse are more adjustable than others.

When you pull a swing trigger, it’s more like pulling a traditional trigger for most paintballers. Instead of traveling straight back, it swings back and up, hence the name. Pulling the trigger drops your sear while also pushing your timing rod forward. These triggers are generally sprung pretty lightly and can shoot really quickly when set up correctly.

A brand new type of swing frame has recently been released by Inception Designs as well. It combines the features of a swing and slider frame. While the internals of the frame and trigger plate remain close to the same as Inception’s slide frames, the front of the trigger plate has been removed, and a lower arm has been added. The swing trigger sits in front of it and pushes the plate back when the trigger is pulled. It allows for the slider plate to be moved back using the trigger as a lever and has adjustment points where the trigger comes into contact with the plate. That means you can adjust the weight of the trigger by adjusting where the set screw in the trigger is, and the screw’s length.

Fill 'er Up

The last major part of the build I’ll cover is the barrel. You know you need one, but what is the right set up. There is a correct answer here. It’s anything with multiple bore sizes. Period.

Here’s why.

Your ball detent does not keep your ball in place. It just stops double feeds. What holds your ball in place is it’s fit in the barrel. As your ball loads into the body, the bolt pushes forward and moves it passed the detent and into the barrel. This is why your barrel matters more with cockers and similarly closed bolt markers than any other type of paintball gun.

The last major part of the build I’ll cover is the barrel. You know you need one, but what is the right set up. There is a correct answer here. It’s anything with multiple bore sizes. Period.

Here’s why.

Your ball detent does not keep your ball in place. It just stops double feeds. What holds your ball in place is it’s fit in the barrel. As your ball loads into the body, the bolt pushes forward and moves it passed the detent and into the barrel. This is why your barrel matters more with cockers and similarly closed bolt markers than any other type of paintball gun.

You do not want your balls to move into different spots in your barrel. It, without question, is a bad thing for you. In paintball, consistency is what most people refer to as accuracy. It’s putting balls into the same spot repeatedly. You are essentially shooting a small water balloon. The way to keep your paint going to the same spot is simple. Eliminate variables.

To go about that, you want to under-bore slightly. That will keep your balls all loading into the same spot. It will also keep the ball in contact with the sides of the barrel, allowing for less wasted air as the pressure behind the ball stays behind the ball. Finally, by keeping the paint touching the walls consistently, the paint is experiencing similar situations as it travels down the barrel (as in air isn’t going around the ball all willy-nilly). This should keep the paint flying out the barrel and landing right next to its family downrange.

I know that you here the term blow-through a lot when talking paint fit to barrel. This is NOT what you want, at all. A blow-through fit will not actually be snug, but means that there isn’t a consistent pressure all the entirety of the ball. This will vary from ball-to-ball, meaning that there are variables between shots. You’re less likely to get consistency this way, and you aren’t going to have paintballs go where you expect them to be.

Under Pressure

Like the mighty mitochondria is the powerhouse of the cell, the HPR is the powerhouse of your ‘cocker. Thankfully, most are pretty well made at this point and will work well. You want one that is externally adjustable, consistent and has a good flow rate. This eliminates a few right off the bat. The older WGP HPRs did not adjust externally without an AKA cap, which is rare. You will likely want to avoid them. Older regulators like Air America’s were nice regulators at the time but have certain seals that are hard to replace and hard to get parts for now. The first few generations of CP regulators are commonplace now but have tested to be less consistent than many other regulators on the market.

To go about that, you want to under-bore slightly. That will keep your balls all loading into the same spot. It will also keep the ball in contact with the sides of the barrel, allowing for less wasted air as the pressure behind the ball stays behind the ball. Finally, by keeping the paint touching the walls consistently, the paint is experiencing similar situations as it travels down the barrel (as in air isn’t going around the ball all willy-nilly). This should keep the paint flying out the barrel and landing right next to its family downrange.

I know that you here the term blow-through a lot when talking paint fit to barrel. This is NOT what you want, at all. A blow-through fit will not actually be snug, but means that there isn’t a consistent pressure all the entirety of the ball. This will vary from ball-to-ball, meaning that there are variables between shots. You’re less likely to get consistency this way, and you aren’t going to have paintballs go where you expect them to be.

Under Pressure

Like the mighty mitochondria is the powerhouse of the cell, the HPR is the powerhouse of your ‘cocker. Thankfully, most are pretty well made at this point and will work well. You want one that is externally adjustable, consistent and has a good flow rate. This eliminates a few right off the bat. The older WGP HPRs did not adjust externally without an AKA cap, which is rare. You will likely want to avoid them. Older regulators like Air America’s were nice regulators at the time but have certain seals that are hard to replace and hard to get parts for now. The first few generations of CP regulators are commonplace now but have tested to be less consistent than many other regulators on the market.

You also will want to make sure that the HPR has standard male threading. While the standard for most of the market, there are some regulators that use different smaller threading or female threading. Avoid them since you can’t use them. Ones that are great performers would be the AKA 2 Liter and Sidewinders, Inception’s HPR, the externally adjustable WGP regulators, Planet Eclipse Star regulators, CCM HPRs, and Palmer’s Stabilizers. As you can see, that’s most of the market.

Unleash the Fury

I learned how to time an Autococker back in the ’90s by reading Ravi Chopra’s Info sheet, and his article on it is still very good today. Here is a link to his site’s page on timing. Here are the very basics in short.

First, if you can Chrono your marker if you can. You don’t want to go through timing then realize that you’re going to have to respring the whole thing to reach velocity. If you can get your FPS correct, you can then time it with minimal adjustment.

Unleash the Fury

I learned how to time an Autococker back in the ’90s by reading Ravi Chopra’s Info sheet, and his article on it is still very good today. Here is a link to his site’s page on timing. Here are the very basics in short.

First, if you can Chrono your marker if you can. You don’t want to go through timing then realize that you’re going to have to respring the whole thing to reach velocity. If you can get your FPS correct, you can then time it with minimal adjustment.

The second thing you’ll want to do is set your back block. This is actually pretty easy. Start screwing your back block onto your pump rod with the ram all the way forward. You want to just be able to see air between your body and the block so that they aren’t slapping each other when cycling. Keep in mind your pressure when aired up will pull the block slightly forward from where you are holding it.

The next thing you want to do is set your cocking rod length. Screw that puppy into your hammer and get it nice and tight so that it’s not going to shake loose. Then start adjusting the knob and bumper. You want to set the cocking rod length so that your bolt clears the breach when you hear and feel the click and the sear catches. There will be over-travel, and that’s okay. You just want to make sure that your bolt is far enough back to allow a ball to drop into the breach when cycling.

Next is setting the hammer’s lug. There is a hole in the top of your body after the feedback going straight down into the bolt. That hole exists to give you access to your hammer lug. Pull out that bolt and slide a hex wrench down the rabbit hole until you feel it lock into the lug. You may have to move the hammer forward or back a little to get it to fit. You’ll want to raise it until the hammer cannot be pushed passed the sear if you are pressing on the cocking knob in the back. Put some real pressure on it there. Once you get it set there, give the hex wrench one more half-turn in the lug. That should drop it to the point that it will cock reliably and hold for cycling yet release softly and on-time in the cycle. It allows for the marker to fire just prior to your three-way cycling.

There are a couple of shapes for you to pick from for your hammer lug. You can have a flat top, rounded, or cone-shaped lug. The flat lugs are generally the most reliable to lock onto your sear, and not slip. They also have the most snap to them. The rounded lugs generally release more smoothly but can also slip more easily. This means that you need more contact with the sear to reliably hold, but again, are very smooth. The gunfighter frames use a cone shape lug that connects to their unique style of sear. The interaction here allows for a very fast trigger pull.

Trigger plates also vary. If you have a trigger plate from after 2000, odds are good that you have a plate with a hole and not a slot. If this is the case for you, you want to set your cocking point right after it fires. To do this, you’ll move the coupler attaching your three-way to your timing rod. Basically, you want your ram to start with pressure directed to the back of it. Start out there in terms of length. Once you have that, you can start moving the cocking point around. Your goal here is to set your o-ring in the three-way so that air pressure is shifted completely just after the point that the hammer is released.

If you have a slotted trigger plate, it’s a bit different. You want to set the actuator so that the block is forward at the firing point and that it cocks after it fires. There is a built-in slop so that the actuator doesn’t cause 3-way over-travel, which can also make you work a little more when timing it. You can use the same process to start, but to test it, air up. Start to slowly pull the trigger so that you are firing your hammer. What you want to make sure of is that your back block isn’t flying back prior to the hammer release. You want the hammer to fire off, and then have your back block recock your marker. This should ensure that your firing cycle is set and that you don’t get blowback.

Conclusion

That’s it. You wanted to do so and can now build and time your Autococker. Once it’s set, remember the basic rule of not to screw with it once it is working. If you do that, they are extremely reliable markers. They’re also some of the best times you can have with pants on.

Go out, grab some parts, and get your build started!

Trigger plates also vary. If you have a trigger plate from after 2000, odds are good that you have a plate with a hole and not a slot. If this is the case for you, you want to set your cocking point right after it fires. To do this, you’ll move the coupler attaching your three-way to your timing rod. Basically, you want your ram to start with pressure directed to the back of it. Start out there in terms of length. Once you have that, you can start moving the cocking point around. Your goal here is to set your o-ring in the three-way so that air pressure is shifted completely just after the point that the hammer is released.

If you have a slotted trigger plate, it’s a bit different. You want to set the actuator so that the block is forward at the firing point and that it cocks after it fires. There is a built-in slop so that the actuator doesn’t cause 3-way over-travel, which can also make you work a little more when timing it. You can use the same process to start, but to test it, air up. Start to slowly pull the trigger so that you are firing your hammer. What you want to make sure of is that your back block isn’t flying back prior to the hammer release. You want the hammer to fire off, and then have your back block recock your marker. This should ensure that your firing cycle is set and that you don’t get blowback.

Conclusion

That’s it. You wanted to do so and can now build and time your Autococker. Once it’s set, remember the basic rule of not to screw with it once it is working. If you do that, they are extremely reliable markers. They’re also some of the best times you can have with pants on.

Go out, grab some parts, and get your build started!